A fiber cement blade, unlike your typical circular saw blades, it comes with special pieces and characteristics that will allow cutting through the fiber cement. Fiber cement is a robust construction material that comprises of cement, sand and cellulose fibers. The inorganic fibers helps to make it a very strong and long-lasting product. It is commonly used for critical sections of houses and buildings including siding, roofing, and floors. Fiber cement, on the other hand is incredibly strong. For this reason, regular saw blades that you use for other materials are difficult to cut. This is where the fiber cement blade can help!

A fiber-cement blade with a diamond-tipped edge is highly resistant to wear and tear. This unique cutting edge enables the blade to slice through hard fiber cement without getting harmed or wearing off after some time. The blade also features a distinctive set of teeth, with spacing along the edge following an established sequence. This will greatly reduce (the amount of) dust & debris generated when you cut. Maintaining the work place clean is important; in this blade, it helps a lot!

There are many worst parts of cutting fiber cement materials under which the first and most annoying part is dusting. Fiber cement tends to create a lot of dust or debris when being cut with any equipment, whether it be wood saws for circular saw blade for plywood. It looks like it is not only messy, breathing those tiny particles can be dangerous. A fiber cement blade should significantly reduce how much dust and debris you would generally experience while working.

Even better, there are some fiber cement blades that have this feature built right in, so the blade itself will collect all of the dust and debris while you cut! They can have a dust collection system or some other means to help channel the dust up and out of where you are working. It is not only a cleaner and more satisfying job but it can also be safer for you to work without breathing too much dust.

Cement-bonded blades: a mix of synthetic and steel material — last longer than both pure types by themselves. As the Wrestlers are manufactured with better quality materials and their design make them durable enough to be used multiple times, you do not need to frequently replace it like other types of Saw Blades. Which means you can use it for many projects!

Safeguarding Other Materials: You will not be hurting the surrounding materials when you are cutting through fiber cement. Since the blade is meant to be this precise, you do not have to worry about accidentally cutting or scratching other sections of your project. The necessity of this directly correlates to the granularity at which you are working on your project.

If you intend to work with composite fiber cement more than just casually for a specific application, then ether get the right blade and cutter or don not do it at all! Having the correct tools available to you means that an able person can complete a project efficiently and correctly. It will also feel good to know that you are equipped with the right tools for your business!

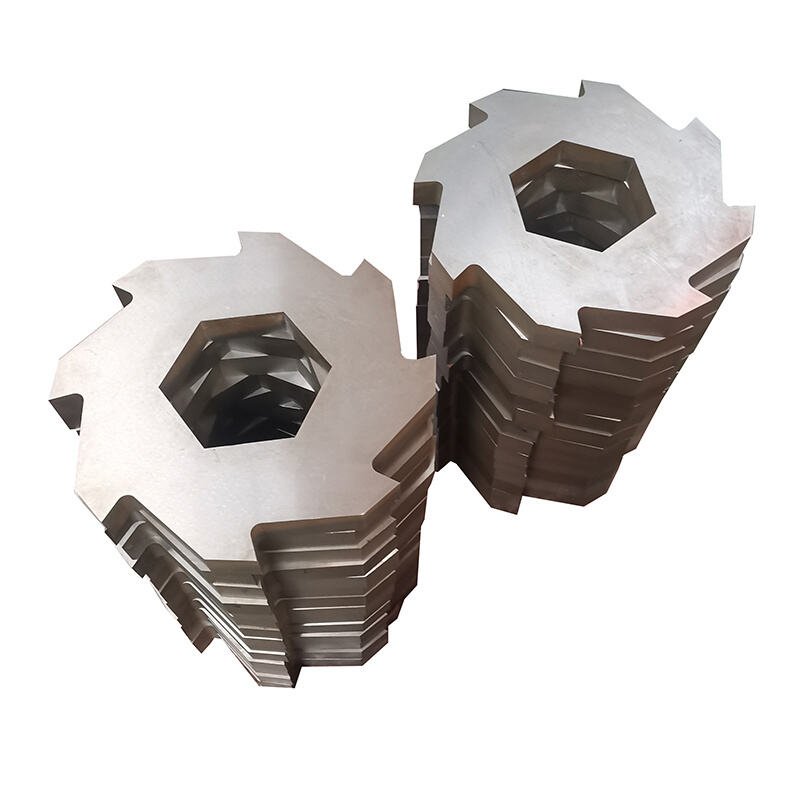

Nanjing Huaxin Machinery Tool Manufacturing Co Ltd places a high priority on quality We use rigorous quality control measures throughout the production process This includes selecting high-quality alloy tool steels that are suitable for the specific tooling applications that utilize sophisticated vacuum heat treatment and deep-cooling methods to increase endurance and performance Our commitment to quality is apparent in our products' resistance to fiber cement blade as well as their toughness and long service life positioning us at the forefront of our industry

Following production every blade is scrutinized with electronic calipers for verification of dimension accuracy as per technical drawings We conduct hardness tests after heat treatment to ensure fiber cement blade to strict quality standards These measures guarantee that our products are able to satisfy or exceed expectations of customers

Our factory is over fiber cement blade square metres and equipped with the most modern equipment This allows us to have to process orders efficiently and with high quality We follow strict quality control procedures to ensure that the raw materials we use are of top quality and that each blade is CNC-machined to ensure maximum precision

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd., a specialized manufacturer, is located in Nanjing City, Jiangsu Province, China. We are focused on the manufacture of a wide range of mechanical blades, such as fiber cement blade, wood chipper blades, shredder blades and the granulator blades. Our expertise lies in customizing and manufacturing the blades to meet needs of our customers, using advanced CNC machines, grinding machines and heat treatment furnaces. milling machines, lathes and sawing machines.