How many of you have experience trying to cut a piece of plywood and having it splinter on its way down the saw? It was the problem of maybe your cut turned out rough, or it looked jagged and uneven. If it sounds like your business — don't worry. There is also something special available that helps you out with it and called a plywood cutting blade which will help solve all of these little problems so when we buy tools, its like an upgrade.

Plywood Cutting Blade is a type of saw that made only cutting plywood. The teeth of this blade are also sharp and angled differently than most other hand saws, leaving behind clean, smooth cuts. You may be getting much difficulty in cutting through plywood, the use of correct blade set up for overhead table saw can do a clean and nice work.

For instance, if you need to slice some thin plyboard a blade that has greater teeth per inch would be ideal. The high number of teeth (72) will allow for a smooth surface because more cuts are made as it passes through the wood. Step three: use a Blade with Less Teeth and Further SpacedIf you are cutting through thicker plywood, opt for fewer teeth spaced further apart. This due to the fact that it can do more cuts at once and with a lot less faster, thus easier on you.

When considering a plywood cutting blade there are some important things to take into account. The first thing is make sure the blade fits your saw and that it will handle cutting 5/8″ thick plywood. Strong Blade: It is essential that the blade be made of a long-lasting material which will survive substantial use. For the burrs found in carbide-tipped blades this is a preferred pick since it has defensive features and gives extra longevity.

A technique that helps is to create a template (like the one I show in cardboard, you would never use metal) allowing you to easily reproduce smooth and precise shapes. A copy of the above will allow us to trace this onto a piece gen1 plywood, and then use blade make precision cuts on that outline. This technique can be very useful in making your edges look nice and professional!

To saw a piece of thick plywood you can always expect some extra labour, but not so much when using the ideal blade! Blades with fewer teeth and a wider set are ideal for working through thick plywood materials without hassle. They make it easy for you to power through the material in a smooth and efficient manner.

Slow your saw down when cutting thick plywood. This will keep the blade from getting too hot and burning both the wood material as well as, eventually, your saw blade. Alternatively, you can apply a lubricant — for instance beeswax or saw blade oil to allow the wood to slide more easily against the teeth. Tip: A game changer for cutting this cake is to place your knife in hot water, then pat it dry — The hotter the blade of the knife (thermodynamic effect) = cleaner cuts!!

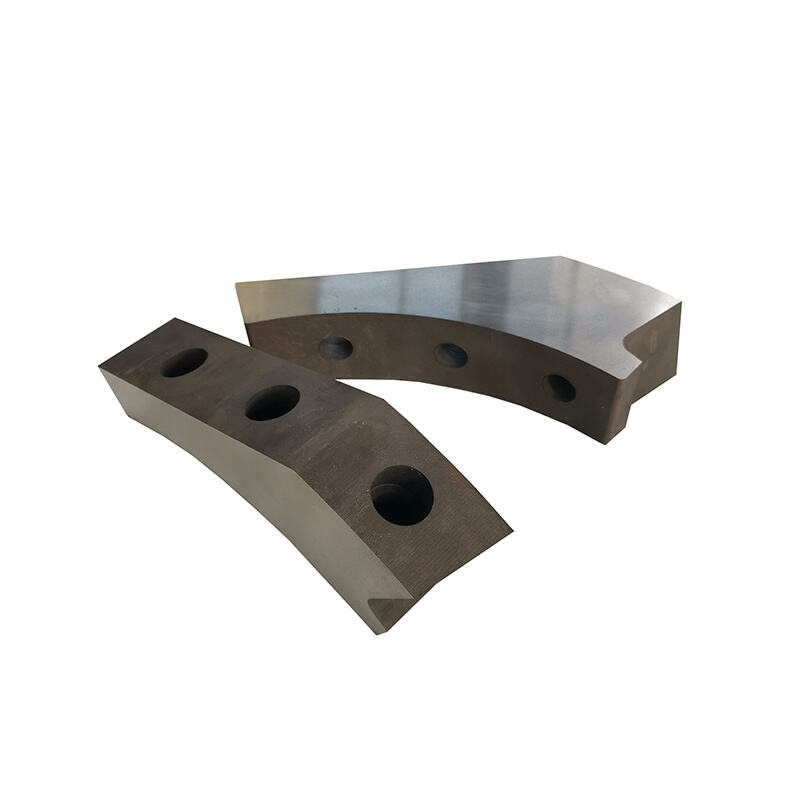

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. is a highly skilled manufacturer located in plywood cutting blade, Jiangsu Province, China. We concentrate on manufacturing the widest range of mechanical blades. These include crusher blades, wood chipper blades, shredder blades and granulator blades. Our expertise is in customizing and manufacturing these blades in order to meet needs of our customers, using advanced CNC machines, grinding machines as well as heat treatment furnaces. lathes, milling machines, and sawing machines.

After the production process each blade undergoes meticulous inspection using electronic calipers to verify dimensional accuracy in line with the technical drawings We conduct hardness tests after plywood cutting blade to ensure compliance with strict quality standards These measures ensure that our products exceed the expectations set by our customers

Our factory is over 8 000 square meters and is outfitted with the most advanced machinery This plywood cutting blade gives us the ability to fulfill orders efficiently and with high quality We adhere to strict quality control measures ensuring that raw materials are of the highest grade and that every blade is subjected to CNC milling to achieve the highest precision

Nanjing Huaxin Machinery Tool Manufacturing Co Ltd place top priority on quality We follow strict quality control procedures throughout the process of production This includes selecting high-quality alloy tool steel that is suitable for the specific applications for tooling using sophisticated plywood cutting blade and deep-cooling methods to increase durability and efficiency We are proud of our commitment to quality which can be seen in the abrasion resistance and toughness of our products as well as their extended duration of service