Sheep shearing blades are one of the most important tools for your sheep farmers. These unique blades are used to shear the wool from sheep. The wool gathered is later used in preparing outfits, blankets and many other things outdoor. Here, in this article let us check a few things — Buying the best sheep shearing blades and how to maintain it well, Differences between 2 types of blads, what blade size is perfect for your sheep shears & Sharpening these blades easy way.

Therefore, you need to ensure when seeking sheep shearing blades available that what they are made of is capable and also really tough in nature. Most high-performance blades are made of top-grade steel. It is a very unique type of steel for these reasons as it holds an edge well and does not rust (as easily) when wet. When you are shopping for knives, it is crucial that blades be razor sharp and have a keen edge; if they do not, this could only potentially SAVE your life one day. A sharp cutting edge helps you work more efficiently and a safer one too when it comes to shearing the sheep.

Proper cleaning of the sheep shearing blades is a must in ensuring their proper functioning. After some time if the blades will not be taken care of properly they will get dull and then it can become hard to shear. Clean your blades after using them to keep in excellent shape. Because that involves taking them off and cleaning any dirt or moss stuck on. Also, some oil on the blades after cleaning is a must as well. This can help prevent rust formation and keep them in proper working order. You should also have your professional sharpen the blade once or twice year. Could give them enough time, whatever they need to perform well.

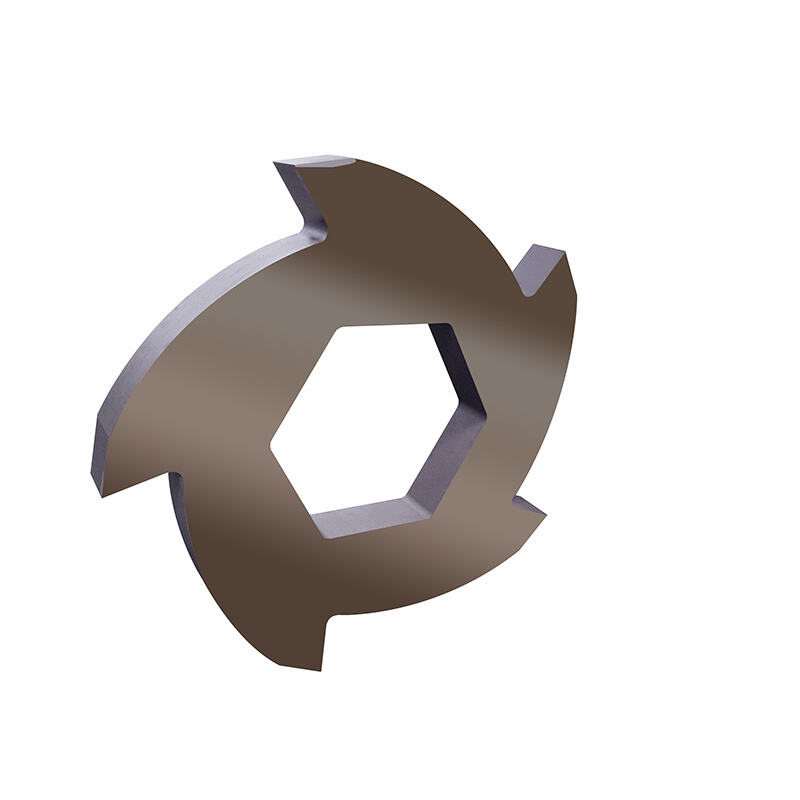

There is only slight difference in standard sheep shearing blades and wide ones for both size and shape. Though standard blades are typically longer and narrower, they excel when performing certain tasks. In contrast, narrow blades are longer and narrower, while wide blades typically shorter but wider. The type of blade you would be using will depend on your sheep size and how much wool you want to cut off from them. As an example, you might choose wide blades if your sheep are big or when you have to do a great deal of shearing. But, if your sheep is not as big or you only want a little hair cut off there then use the standard blades.

So there you have it – available in 3 sizes, selecting the right size when purchasing sheep shearing blades for your flock is crucial. Ensure the Blades Fit Your Sheep If say you get blades that are too small for your sheep, then it will take longer to shear all the wool and they might not even come off. It can get frustrating, and some wool might stay behind. Larger clippers are more difficult to maneuver without tearing through your sheep by mistake. For this reason, it is crucial to select sheep clipping blades of an appropriate size for your animal and also ones that you are comfortable in handling. Find the size that works best for you, and I promise it will help with your shearing — not to mention keep everyone around you a lot safer.

Sheep blade sharpening in your house can be fairly straightforward so long as you follow the proper steps. Before anything else, Clean the blades by scraping off all that rust or dust from them. It means you are working with a blank canvas. If purchase, remember to use a sharpening stone or file afterwards as the cleaning and ethanol will dull your blades. When sharpening do so at a 45 degree angle across the blade with your stone or file. Just follow the correct direction of how blade is cutting. Keep doing that on both sides of the blade until you are happy with how sharp it is. The following step is to not forget oiling blades after sharpening. Do not skip this part as rust can be a problem and then, air it! which keeps the blades in use for longer.

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. is a highly skilled manufacturer located in sheep shearing blades, Jiangsu Province, China. We concentrate on manufacturing the widest range of mechanical blades. These include crusher blades, wood chipper blades, shredder blades and granulator blades. Our expertise is in customizing and manufacturing these blades in order to meet needs of our customers, using advanced CNC machines, grinding machines as well as heat treatment furnaces. lathes, milling machines, and sawing machines.

Our facility is more than 8000 square meters and is equipped with the latest machinery This allows us to effectively fulfill orders with a high degree of precision and high quality We strictly sheep shearing blades to quality control measures to ensure that our raw materials are of the highest standard and that every blade undergoes CNC milling to achieve the highest precision

After the production process each blade undergoes meticulous inspection using electronic calipers to verify dimensional accuracy in line with the technical drawings We conduct hardness tests after sheep shearing blades to ensure compliance with strict quality standards These measures ensure that our products exceed the expectations set by our customers

Nanjing Huaxin Machinery Tool Manufacturing Co Ltd place an emphasis on the quality of its We use rigorous quality control methods throughout the process of production In order to increase durability and effectiveness we utilize high-quality sheep shearing blades specifically designed for tooling applications We also employ the latest vacuum heat treatments as well as deep cooling techniques We're proud of our commitment to high-quality as evident in the toughness and abrasion resistance of our products and their long service life